How the Glass Industry Has Changed Recently

Each sector of the glass industry has its own unique characteristics and production processes, but glass melting is universal. This physical process involves raw materials, energy and state-of-the-art production facilities. It behooves glass manufacturers to have good environmental management systems and to make significant expenditures in order to stay competitive globally.

BPS Glass concentrates its efforts on these shared difficulties to exchange experience, information and best practices, in order that Florida remains a leader in glass manufacturing.

Recycling is our responsibility

Glass is the best packaging material. People are not often aware that glass is created entirely of natural elements and can be recycled indefinitely without causing harm to the environment. As an industry, we’ve implemented various measures to reinforce this message, ranging from partnerships with local nightlife destinations to campaigns to improve people’s recycling practices. Many individuals are unaware of the impact: they deposit their glass in a bottle bank or collection bin, and that is “the end of it”. They often believe everything is automatically sorted and dealt with. Still, if every glass collection contains items that shouldn’t be there, the business quickly becomes challenging.

We must care about our planet for future generations, and if this means each of us must recycle a small amount of glass on a daily basis (and take the time to do so properly), that is not too much to ask. On the plus side, a stroll to the bottle bank is a great way to get out of the house these days!

Today’s glass manufacturing sector

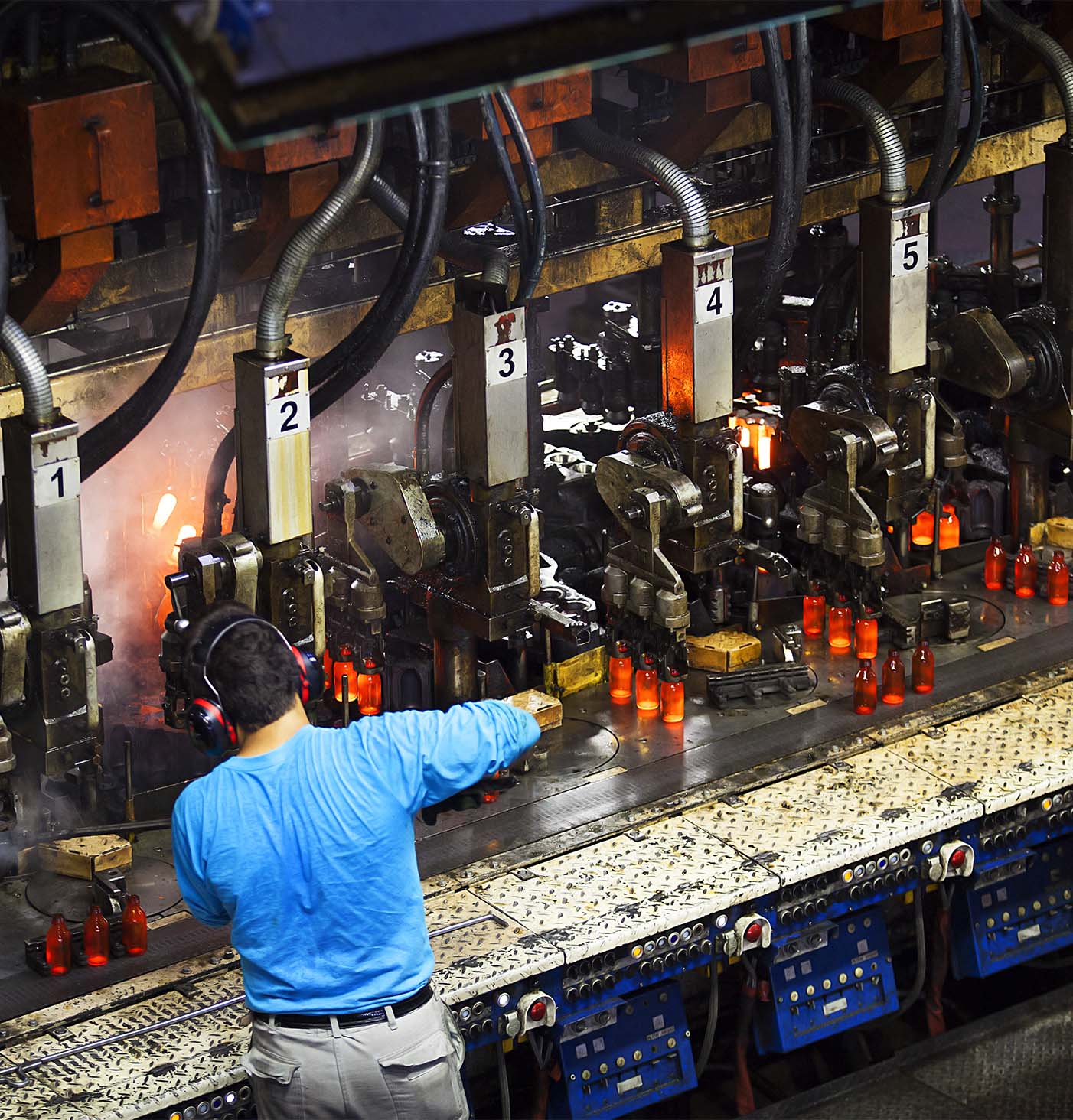

Manufacturing facilities for container glass rely on high-temperature furnaces which must constantly operate 24 hours a day. The furnace, which cannot be switched off or idled, takes months to restart after being shut down, emphasizing the need for a fully functioning and operating supply chain. The furnace is the process’s heart and it normally functions for around 8-10 years before being replaced.

Rebuilding the facility requires a significant financial expenditure and takes around 4-5 months to implement. Furthermore, if operations are halted during campaign time, substantial damage to the furnace may ensue. The furnace operates on a constant supply of natural gas; a furnace with a daily output of 1,000 tons holds around 3,000 tons of molten glass at any one moment.

This is a key procedure which needs a continuous supply of gas and utility assistance. Additionally, the furnace’s integrity depends on its temperature profile, and any loss of firing/incorrect temperature management can irreparably harm the furnace beyond usage, resulting in the business’s collapse.

The glass sector has encountered several obstacles due to the COVID-19 epidemic, global lockdowns, and the closure of non-essential operations to comply with COVID-19 safeguards. Consumer purchases of several staple food goods surged from 10% to 60% during the COVID-19 epidemic. And demand will only rise in the coming months. Disrupting the glass container business and supply chain could have a detrimental effect on the world’s ability to acquire pharmaceutical, food, and beverage items in stores at a time when such outlets are crucial to the world’s food supply.

For more information on the critical importance of the glass industry, visit bpsglass.com or call us in South Florida at +1 470 864 3065.